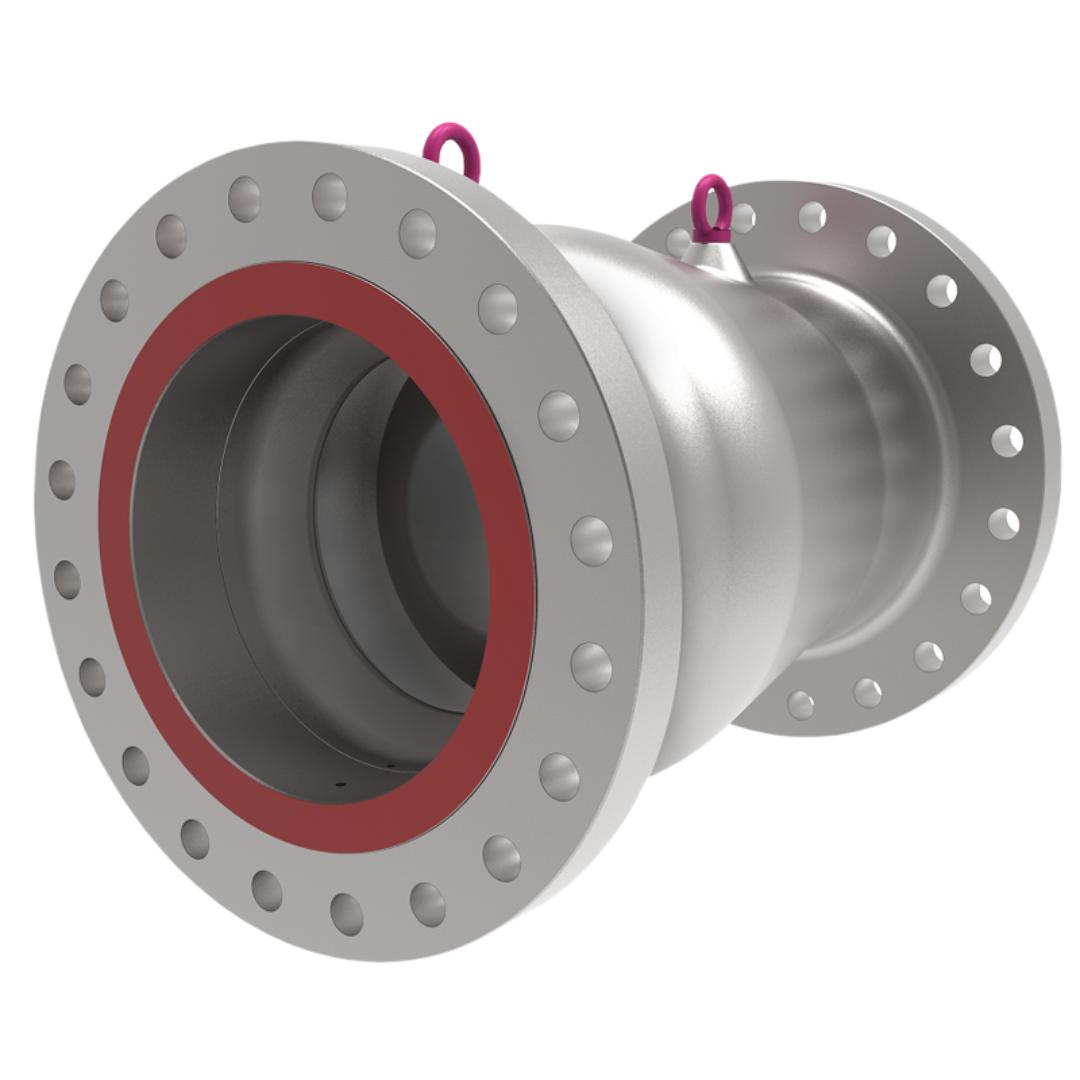

AXIAL FLOW CHECK VALVE

axial flow check valves are widely used where high flow performance is required and the risk of water hammer needs to be reduced to a minimum level. Additional advantages include the quick response and low noise level.

Size: NPS 2″~60″(DN50~DN1500)

Pressure Rating: ASME CLASS 150~2500(PN16~PN420)

Body material:Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End connection:RF, BW, RTJ

محصولات

ارجینال

گارانتی و وارانتی

محصولات

ضمانت بازگشت

و تضمین اصالت

پشتیبانی

اختصاصی

قیمت محصول

برای قیمت تماس بگیرید

An axial disc check valve prevents rapid reverse flow from a pipe, known as “water hammer,” which can damage pipe system equipment severely. A valve of this type closes quickly enough to prevent slamming without excess spikes.

Spring assisted axial flow check valve features contribute to its non-slam closing and low maintenance. Its streamlined design allows it to be fully opened at low flows and flow rates.

Under normal flow conditions, the disc remains positioned against its backstop due to the Venturi effect, allowing a rapid full opening. When the flow is reduced, the spring quickly overcomes the fluid force, turning the disc back into a full close position. With a slam-free response, this system protects critical pipeline elements by significantly reducing the reaction time.

There are many applications for these kinds of valves, including oil & gas, petrochemical, power generation, chemical… They are used in any process where water hammering is an issue. They’re an alternative to Quick Closing Non Return Valves assisted by actuators and used in systems with higher protection requirements.

Advantages of Using Axial Flow Check Valves

Axial flow check valves provide several advantages when compared to other check valve types, including:

- Swift Closing Action: They can rapidly close, effectively preventing water hammering and associated damage.

- Tailored Sizing: These valves can be accurately sized for each specific application, optimizing their performance.

- Durability: Axial flow check valves are known for their robust construction, ensuring long-lasting performance.

- Extended Lifespan: Their durability contributes to an increased valve longevity, reducing maintenance and replacement costs.

- Low-Pressure Drop and High Flow Capacity: These valves can handle high flow rates while maintaining low-pressure drops, promoting efficient fluid system operation.

- Non-Slam Operation: They open and close without slamming, reducing wear and tear on the valve and system components.

- Tight Seal: Axial flow check valves provide a tight shut-off, minimizing leakage and enhancing system integrity.

- Versatile End-to-End Options: They offer various end-to-end connection options, making them adaptable to different piping configurations.

- Flexible Installation: These valves can be installed in both horizontal and vertical orientations, accommodating diverse system designs and requirements.

In summary, axial flow check valves deliver a range of benefits, including rapid closing, tailored sizing, durability, extended lifespan, efficient flow management, non-slam operation, tight sealing, adaptability, and flexible installation, making them a preferred choice in various fluid control applications.

نقد و بررسیها

حذف فیلترهاهنوز بررسیای ثبت نشده است.