نمایش 37–48 از 189 نتیجه

جشواره فروش محصولات اپل

برای تغییر این متن بر روی دکمه ویرایش کلیک کنید. لورم ایپسوم متن ساختگی با تولید سادگی نامفهوم از صنعت چاپ و با استفاده از طراحان گرافیک است.

زمان باقی مانده تا اتمام جشواره

فیلتر های فروشگاه

دستههای محصولات

- پایپینگ ۱۰۲

- تجهیزات تست ۱۷

- مکانیکال ۱۶

- مواد شیمیایی ۲

- Filter ۱

- ولو ۵۲

- ACTUATED VAVES ۶

- MANUAL VALVES ۴۲

- API 6A VALVE ۴

- BALL VALVE ۱۰

- BUTTERFLY VALVE ۵

- CHECK VALVE ۵

- CHOKE VALVE ۴

- CRYOGENIC VALVES ۳

- GATE VALVE ۳

- GLOBE VALVE ۳

- PLUG VALVE ۵

- SAFETY VALVE ۴

Detonation Proof In-line Flame Arrester

برای قیمت تماس بگیریدThe flame arrester is designed to prevent flame transmission when

flammable gas/air- or vapor/air-mixtures are presented.

The model DFA / UDFA /EDFA in-line flame arrester is designed, manufactured and tested according to API 2000 and ISO 16852, IMO MSC Circ 677.

Body material of arrester is available of nodular cast iron, cast steel, stainless steel grade 304, 316, 316L and special alloy steel for chemical resistance.

The material of element is available of stainless-steel grade 316L or special alloy steel for chemical resistance.

The flame element is constructed with crimped ribbon metal.

DNV MED and ATEX Approved with stable detonation flame arrester (DFA, EDFA) and unstable detonation flame arrester (DFA, UDFA)

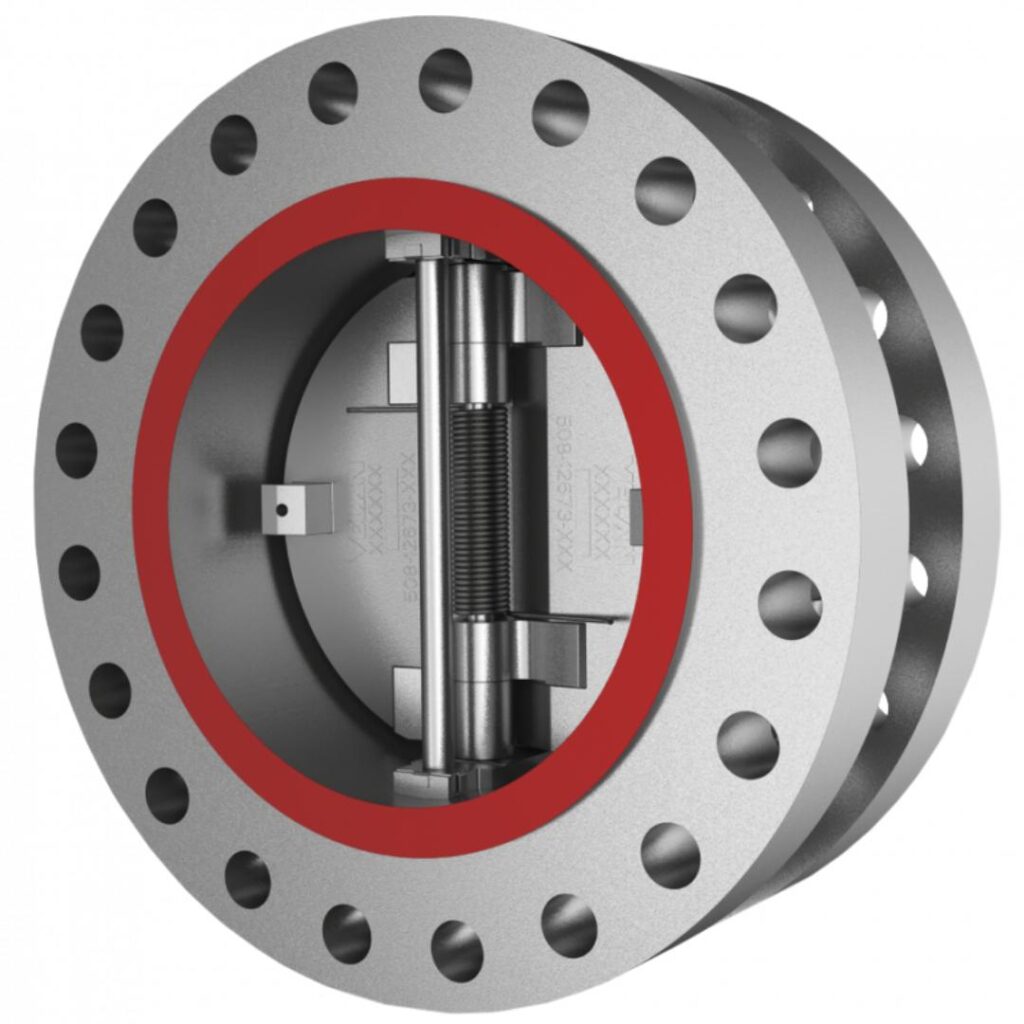

DUAL PLATE

برای قیمت تماس بگیریدDual plate check valves are used to protect installations against backflow. They are entirely operated by reaction of flow and they do not require any external actuation.

The main advantages of dual plate check valves vs swing check valves are: lightweight, short dimensions. Moreover, line shock is reduced or eliminated. Due to the reduced face to face this check valve can be mounted vertically or horizontally thanks to a return spring.

Dual check valve can be designed as wafer, lug or flanged type.

ECCENTRIC TYPE

برای قیمت تماس بگیریدEccentric Type Butterfly Valve

The eccentric type butterfly valve has three categories and they are – single-offset, double-offset and triple-offset. The availability of single-offset valves is rare in the marketplace whereas double-offset and triple-offset are the commonly used ones.

Oftentimes, these two sub-type of eccentric butterfly valves are also referred to as high-performance butterfly valves. The double-offset valve comprises two offset. The first one is located slightly behind the disc and it helps in making the valve have a consistent sealing surface on the disc.

Whereas the second offset is situated on the slightly right side of the disc’s center. This offset works to prevent the valve from coming in contact with the seat when it is completely open. This arrangement of the seating design helps in less friction and contributes towards prolonged service.

The triple-offset valve on the other hand has three offset and the first two offset does the same job as double-offset one. Only the third and additional offset of this valve has a conical shaped seating which is made to match with the disc that is also fabricated to match with the seating.

This seating arrangement helps in preventing friction or rubbing completely while it’s opening or closing. It also enables the valve to have a bubble-tight performance in the high-pressure application and have a much longer lifespan in comparison to double-offset butterfly valves.